Corporate Headquarters

3525 Whitehall Park Drive, Suite 400, Charlotte, North Carolina 28273

Phone: (704) 594-3800

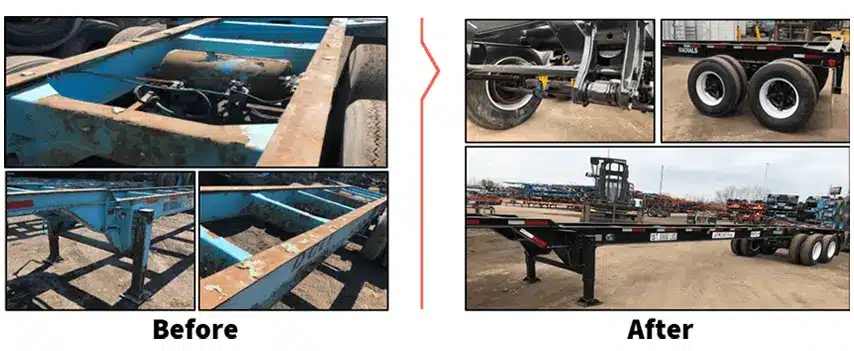

Providing Motor Carriers with the equipment they need to get the job done is important to us. That’s why we’re investing millions in our chassis refurbishment program.

“We know that motor carriers rely on our equipment to do their jobs,” said Ron Joseph, COO and EVP of DCLI. “Our focus is on making sure that the equipment bearing the DCLI logo is up to the task for our customers and, to that end, we have invested $95 million dollars on chassis quality improvement initiatives.”

Watch our video to see how we refurbish chassis.

Our team meticulously inspects each refurb chassis and upgrades them with the following components:

New recap radial tires

New LED lights

New paint

New electrical receptacle

New glad hands

New air lines

New brake hoses

New electrical harness

New conspicuity tape

New mud flaps

New decals and markings

New slack adjusters

New camshaft bushings

New inner and outer bearings and races

New hub caps and seals

New drums

New brake shoes and hardware

New spring brakes

New wheel clamps, studs, and nuts

New emergency valve

Our refurbished chassis are available through Direct ChassisLink Leasing.

Learn more about our refurbished chassis here.

3525 Whitehall Park Drive, Suite 400, Charlotte, North Carolina 28273

Phone: (704) 594-3800

General

Email: DCLCHASPNW@dcli.com

General

Email: DCLCHASMTN@dcli.com

General

Email: DCLCHASGULF@dcli.com

Jacob Dixon

Title: Cleveland, Cincinnati, Columbus, Lousiville

Phone: 704-447-3241

Email: jacob.dixon@dcli.com

Paul Cochran

Title: Kansas City, St. Louis, Minneapolis, Omaha

Phone: 704-631-3207

Email: Paul.Cochran@dcli.com

General

Email: DCLCHASMWR@dcli.com

Lashana Davis

Title: Baltimore, Buffalo, Elizabeth, Philadelphia, Pittsburgh

Phone: 704-447-3225

Email: LaShana.Davis@dcli.com

General

Email: DCLCHASNER@dcli.com

Kim Erwin

Title: Memphis, Nashville, Huntsville, Tampa

Phone: 704-954-8362

Email: kimberly.erwin@dcli.com

General

Email: DCLCHASSAR@dcli.com

Phone: 704-594-3800, Option 5 then press 8

Email: domesticoperations@dcli.com

Phone: 704-594-3786

Email: domesticusageclaims@dcli.com

Email: domesticar@dcli.com

Email: domesticusageclaims@dcli.com

Rod Logan

Title: Senior Director, M&R (Philadelphia, Baltimore)

Phone: 606-922-1367

Email: Rodney.Logan@dcli.com

Rod Logan

Title: Senior Director, M&R (Philadelphia, Baltimore)

Phone: 606-922-1367

Email: Rodney.Logan@dcli.com

Dawn Causey-Hall

Title: M&R Specialist II, Southeast

Phone: 912-312-3110

Email: Dawn.Causey-Hall@dcli.com

Chris Munsell

Title: RVP of M&R. Midwest & West Coast

Phone: 630-272-1512

Email: Christopher.Munsell@dcli.com

John Arnspiger

Title: Senior Director of M&R, Houston

Phone: 281-299-6950

Email: John.Arnspiger@dcli.com

Chandi Williams

Title: Sr. Logistics Manager, West Coast

Phone: 657-334-7047

Email: Chandi.Williams@dcli.com

Chris Munsell

Title: RVP of M&R, Midwest & West Coast

Phone: 630-394-3659

Email: Christopher.Munsell@dcli.com

Jeremy Tolleson

Title: Director, M&R (Memphis, Nashville, Huntsville, Kansas City, St. Louis)

Phone: 901-686-1308

Email: Jeremy.Tolleson@dcli.com

Derek Daily

Title: M&R Specialist II, Southeast (Memphis, Nashville, Huntsville, Kansas City, St. Louis)

Phone: 910-395-4103

Email: Derek.Daily@dcli.com

John Arnspiger

Title: Senior Director of M&R, Houston

Phone: 281-299-6950

Email: John.Arnspiger@dcli.com

Rod Logan

Title: Director, M&R (Philadelphia, Baltimore)

Phone: 606-922-1367

Email: Rodney.Logan@dcli.com

Dawn Causey-Hall

Title: M&R Specialist II, Southeast

Phone: 912-312-3110

Email: Dawn.Causey-Hall@dcli.com

Michelle Gomez

Title: Director, Motor Carrier Sales-Western Region

Phone: 951-488-6096

Email: Michelle.Gomez@dcli.com

Cameron Frank

Title: Director, Motor Carrier Sales-Eastern Region

Phone: 312-965-8768

Email: Cameron.Frank@dcli.com

Brandon Sauers

Title: Area Sales Manager, Southeast

Phone: 912-803-8188

Email: Brandon.Sauers@dcli.com

Tommy Tabasco

Title: Area Sales Manager, Northeast

Phone: 201-463-8557

Email: Tommy.Tabasco@dcli.com

Timothy Kirkpatrick

Title: Area Sales Manager, Northeast

Phone: 201-463-8557

Email: Timothy.Kirkpatrick@dcli.com

Charles Freeman

Title: Area Sales Manager, West Coast

Phone: 213-310-1224

Email: Lawrence.Freeman@dcli.com

Albert Wells

Title: Inside Sales Representative-Eastern Region

Phone: 704-631-3209

Email: Albert.Wells@dcli.com

Romeo Joson

Title: Inside Sales Representative-Western Region

Phone: 657-334-7033

Email: Romeo.Joson@dcli.com

Ruel Nuqui

Title: Inside Sales Representative-Western Region

Phone: 657-334-7008

Email: Ruel.Nuqui@dcli.com

Dennis Reiner

Title: National Account Manager, Domestic

Phone: 980-216-6670

Email: Dennis.Reiner@dcli.com

For General Inquiries

Email: domesticcommercial@dcli.com